Welcome to Zaic Design!

At Zaic Design, we are a vibrant and dynamic engineering company fueled by the

passion and creativity of our young and talented team. Our mission is to push the

boundaries of innovation and deliver exceptional solutions in the fields of Industrial

Design, Product Engineering, Precision Prototyping, and Industrial Automation.

With our team of highly skilled engineers, designers, and technologists, we bring a fresh

perspective to every project we undertake. We believe in the power of collaboration,

constantly challenging ourselves to explore new ideas and embrace emerging

technologies. Our youthful spirit, combined with a strong foundation in engineering

principles, allows us to provide innovative solutions that not only meet but exceed our

clients’ expectations.

Industrial Design:

At Zaic Design, we understand that aesthetics and functionality go hand in hand. Our industrial design experts possess an innate ability to blend art and science, crafting visually appealing products that seamlessly integrate with the end- user’s needs. Whether it’s consumer electronics, furniture, or any other product, our team brings a unique touch to every design, ensuring an exceptional user experience.

Product Engineering:

In today’s fast-paced world, successful products require a solid engineering foundation. At Zaic Design, our dedicated product engineering team combines their expertise with cutting-edge technologies to transform concepts into reality. We meticulously analyze, prototype, and refine every detail to ensure our clients’ products are not only innovative but also robust, manufacturable, and scalable.

Precision Prototyping:

Prototyping is at the core of our design process. Zaic Design is equipped with state-of-the-art facilities, allowing us to create precise and functional prototypes quickly. Our prototyping capabilities enable us to iterate and validate design concepts, ensuring optimal performance and reducing time to market. We embrace emerging technologies like 3D printing, CNC machining, and rapid prototyping techniques to deliver high-quality prototypes that match our clients’ vision.

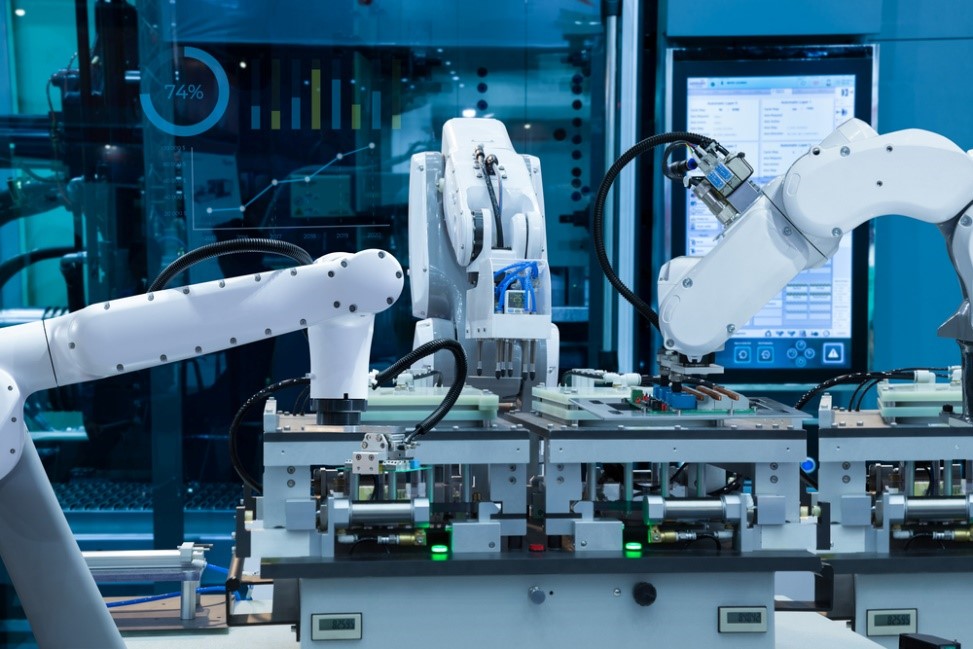

Industrial Automation:

Zaic Design believes in the power of automation to enhance productivity and efficiency in manufacturing processes. Our team of automation experts specializes in developing customized solutions to streamline production lines, optimize workflows, and integrate smart technologies. We leverage the latest advancements in robotics, artificial intelligence, and machine learning to create intelligent automation systems tailored to our clients’ specific requirements.

At Zaic Design, we take pride in our ability to turn complex challenges into innovative

solutions. Our young, talented engineers are driven by a passion for engineering

excellence and a desire to make a lasting impact. We believe in fostering a creative and

collaborative environment that nurtures the growth and development of our team

members.

We invite you to join us on this exciting journey of innovation and engineering

excellence. Partner with Zaic Design, and together we can bring your ideas to life with

an unmatched level of precision, creativity, and professionalism.

Let’s create the future, today.

Zaic Design LLC

Design and Engineering Office

3490 US Route 1, Unit 19-B2

Princeton, NJ 08540

Mon – Fri 8:00-17:00

Mobile: 609-619-9737

Office: 609-540-1300

Email:

Click here to email us

MAP