NJ Custom Industrial Automation Integrator

We develop purpose-built flexible automation solutions.

Our custom approach means we can create a solution that fits your unique business. We take the time to understand your business and requirements before we start thinking about the solution. We offer:

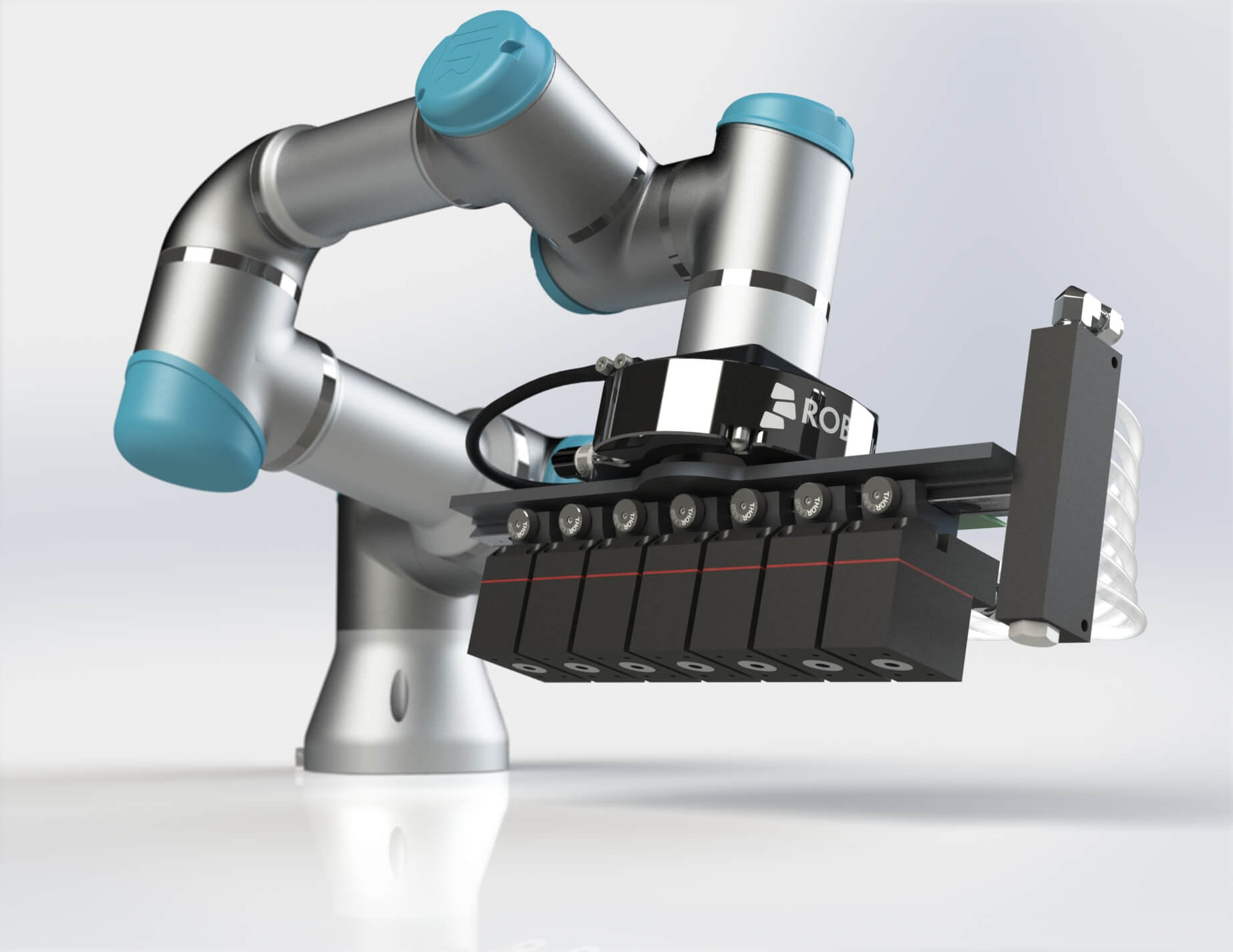

Robot

Integration

Seamless incorporation of robots and machines to improve your existing assembly or QC process

Benchtop

Semi-Automatic Machines

Single purpose, operator tended equipment

Custom

Standalone Machines

Single or multi-process

Allows for a repeatable process for critical and precision operations

Send Us Your Most Challenging Problems

We are an industrial automation solutions provider with roots in Research and Development. We actively seek out automation challenges beyond simple robot integration.

We enjoy nuanced applications that require creative custom solutions. Our specialty is automation involving data acquisition or integration of existing proprietary equipment.

Examples:

- Precision dosing and dispensing of viscous materials

- Material handling applications

- Precision research and development testing operations

- Automated product testing or calibration device

Key Benefits

Optimize Quality

Control your processes with

numerical precision via touch

screen controls.

Maximize Speed

Simplify challenging, repetitive

tasks. Reduce training time

Reduce Waste

Lower scrap rate and material

waste via precision metering

and process tuning.

Purpose-Built Solutions for All Your Industrial Needs

Whether you need help integrating a collaborative robot to improve efficiency or need a completely custom workcell, we can help.

We Make the Most Complex

Automation Challenges Possible

Industries we have worked with:

- Aerospace

- Consumer Electronics

- Personal Care Products

- Medical Devices

- Precision Instrumentation

- Scientific Research Labs

- Standardized Testing Equipment

- Manufacturing

How We Work

Understand the Application

We meet with our clients to understand their automation objectives and develop custom solutions that provide the best return on investment

Study the Process

We assess our client’s current manufacturing processes and materials to learn the challenges driving their automation efforts.

Concept Development

We compile the key elements of the automated solution, identify any risks and challenges, and provide a budgetary quote and lead times so you can move forward with your project as quickly as possible

Feasibility Study

This helps prove out design concepts and allows us to provide a more accurate budget and timing estimates.

Final Proposal

Once the concept development and feasibility study phases are complete, we provide a detailed statement of work, including a phased approach to the final design.

Design and Engineering

By this time, most of the design work is roughed out. We complete the design process and review it with the customer to ensure they are happy with its direction.

Assembly and Testing

We complete the build of the system and conduct rigorous stress tests using customer-supplied materials.

Documentation and Certifications

We provide user manuals and other required technical certifications, ensuring that our clients can operate and maintain the system with ease.

Final Install and Training

We install the automated solution to the customer’s factory site for acceptance testing and operator training. This allows us to ensure that the system is ready for use and that our clients are comfortable with how to operate it.

We Think Past Your Present Systems

Companies looking to automate for the first time are often attracted to the easy integration of collaborative robot arms like the UR series, but may be better served by a purpose-built automated work cell, depending on the application. Working with an experienced custom automation integrator is important to get the most out of our investment.

We don’t just “integrate” collaborative robots or custom equipment. We think about your process and what you are really trying to achieve with automation. We custom design and engineer solutions.

What Clients Are Saying

“We were all very impressed with the quality of the work you demonstrated.”

“What you provided in this short amount of time has far exceeded my expectations of what was possible. I am thrilled. Our jar filling speed improved by 500%, and process loss was down 67% compared to filling by hand!”

LET’S TALK

Contact us today to find out how we can help you with your industrial automation needs. We think outside the box and can provide custom solutions to improve your efficiency and bottom line.

Zaic Design LLC

Design and Engineering Office

3490 US Route 1, Unit 19-B2

Princeton, NJ 08540

Mon – Fri 8:00-17:00

Mobile: 609-619-9737

Office: 609-540-1300

Email:

Click here to email us